Manufacturing Process

2000 parts of dry leaves of digitalis lanata are finely ground with 500 parts of

sodium chloride, they are then wetted with 1000 parts of water and extracted

with 30,000 parts of chloroform. The filtered extract is completely evaporated

in vacuum at a low temperature and to the remaining residue are added 1000

parts of dry ether and the whole mixture is left under the ether until the thick

viscous mass has been transformed into a hard body. The ether is then

poured away and the residue is digested with 1000 parts of ether for about 2

hours under a reflux condenser. After cooling down the mixture, it is filtered,

and the residue obtained, which is now in form of a brittle mass, which is then

dried in vacuum in order to completely eliminate the remaining ether present,

and pulverized. The pulverized mass is advantageously subjected once more

to the treatment with ether. The yellow greenish powder thus obtained is then

dissolved in 1000 parts of methyl alcohol and to the solution, so obtained a

fine suspension of 30 parts lead hydroxide in 1000 parts water is added with

stirring. The solution obtained is neutralized, stirred for about 2 hours, andfiltered, and the clear yellowish filtrate is preferably treated again with a small

quantity of tannin precipitating substance. The clear filtrate thus obtained is

concentrated in vacuum at a low temperature to about 200 parts, whereby the

difficultly soluble portion of the glucoside mixture precipitates. The solution is

then filtered. The precipitate is dissolved in a small quantity of methyl alcohol

and is treated with a small quantity of water whereby the new product begins

to precipitate in a crystalline form. By repeated crystallization from methyl

alcohol, without addition of water, the glucoside may be obtained in the form

of a perfectly pure compound; it does not change its properties even on

further recrystallization. The glucoside, freshly crystallized from methyl alcohol

and dried in vacuo, had MP: 248°C with decomposition, when heated rapidly.

At 230°-235°C, the substance begins to sinter and becomes quite soft; the

melting point, therefore, is not well defined.

Purification Methods

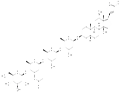

Crystallise lanatoside C from MeOH. Its solubility is : 1/17000 (H2O), 1/45 (EtOH) and 1/1500-2000 (CHCl3). [Stoll et al. Helv Chim Acta 16 1049 1933, Stoll & Kreis Helv Chim Acta 35 1318 1952, Okada et al. Chem Pharm Bull Jpn 23 2039 1975, Beilstein 18 III/IV 2455.] It is cardiotonic.