A kind of preparation method of dapagliflozin

Background and overview

Dapagliflozin is a new type of anti-diabetic drug jointly developed by Bristol-Myers Squibb and AstraZeneca. SGLT2 inhibitors for the treatment of type 2 diabetes can be used as an important option in the treatment of diabetes drugs, and can be used as an adjunct to diet and exercise to improve blood sugar control in adults with type 2 diabetes. Dapagliflozin is an inhibitor of sodium-glucose cotransporter 2, a protein in the kidneys that allows glucose to be reabsorbed into the bloodstream. This allows excess glucose to be excreted through the urine, thereby improving blood sugar control without increasing insulin secretion. Use of this drug requires patients with normal renal function and is contraindicated in patients with moderate to severe renal insufficiency. This product alone or in combination with metformin, pioglitazone, glimepiride, insulin and other drugs can significantly reduce HbA1c and fasting blood glucose in patients with type 2 diabetes, the incidence of adverse reactions is similar to placebo, and the risk of hypoglycemia is low, which can be alleviated weight. Dapagliflozin is comparable in efficacy to several newer antidiabetic drugs, including dipeptidyl peptidase inhibitors, and can slightly lower blood pressure and body weight.

Preparation【1-3】

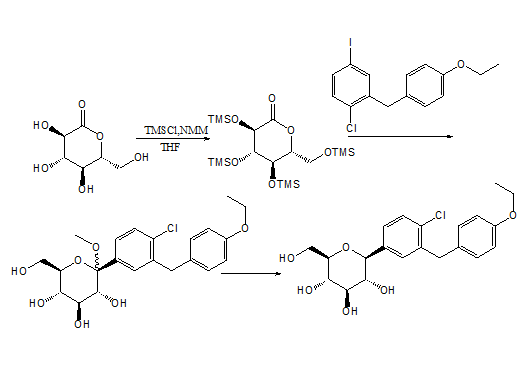

A suspension of the D-(+)-gluconic acid-delta-lactone(42.0kg),tetrahydrofuran(277.2kg),4-methylmorpholine (NMM;152.4kg) and 4-dimethylaminopyridine (DMAP; 1.44 kg) is treated with chlorotrimethylsilane (TMSCl; 130.8 kg) within 50 min at 13 to 19° C. After completion of the addition stirring is continued for 1 hr 30 min at 20 to 22° C. and the conversion is determined via HPLC analysis. Then n-heptane (216.4 kg) is added and the mixture is cooled to 5° C. Water (143 kg) is added at 3 to 5° C. within 15 min. After completion of the addition the mixture is heated to 15° C. and stirred for 15 min. The stirrer is switched off and the mixture is left stand for 15 min. Then the phases are separated and the organic layer is washed in succession two times with water (143 kg each). Then solvent is distilled off at 38° C. under reduced pressure and n-heptane (130 kg) is added to the residue. The resulting solution is filtered and the filter is rinsed with n-heptane (63 kg) (filter solution and product solution are combined). Then solvent is distilled off at 39 to 40° C. under reduced pressure. The water content of the residue is determined via Karl-Fischer analysis (result: 0.0%). 112.4 kg of the product is obtained as an oil (containing residual n-heptane, which explains the yield of >100%). The identity of the product is determined via infrared spectrometry.

Arylmagnesium Formation: A three-necked round-bottom flask equipped with thermometer and jacketed addition funnel was charged with a solution of l-chloro-2-(4- ethoxybenzyl)-4-iodobenzene (7.45 g, 20 mmol) and THF (15 mL) and the mixture was magnetically stirred and kept under an argon atmosphere. To the solution was added zPrMgCl-LiCl (17.7 mL, 1.3 M in THF, 23 mmol) dropwise over 30 min between -5 to 0 °C. The mixture was stirred for an additional 1.5 h at -5 to 0 °C.Gluconolactone Solution: A 100 mL round-bottom flask was charged with (3R,4S,5R,6R)-3,4,5-tris(trimethylsilyloxy)-6-((trimethylsilyloxy)methyl)tetrahydropyran-2- one (12.1 g, 26 mmol) and n-heptane (18.5 mL) and the mixture was cooled to -5 °C under argon. z'PrMgCl-LiCl (0.8 mL, 1.3 M in THF, 1 mmol) was added dropwise and the mixture was stirred for 30 min at -5 to 0 °C. The cooled gluconolactone solution was added dropwise to the arylmagnesium over 30 min at a temperature between -5 and 0 °C. After the addition was completed, the mixture was stirred for 2 h at -5 °C. A pre-cooled (0 °C) solution of concentrated hydrochloric acid (6.7 mL, 80 mmol) in methanol (35 mL) was added dropwise to the reaction mixture while keeping the temperature below 0 °C. The mixture was allowed to warm to 15 to 20 °C and stirred for additional 16 h. The mixture was cautiously quenched with saturated aqueous sodium bicarbonate (-20 mL) to pH weakly basic and the mixture was extracted with ethyl acetate (2 x 80 mL). The combined organic layers were washed with deionized water (100 mL), brine (100 mL), dried over sodium sulfate, filtered and concentration under vacuum to give 7.87 g of product as a light yellow glassy solid. Yield: -90%. Purity (LC-MS Method EGT-M-0013) 3.0 min, 80% (UV); MS ESI (m/z) 439[M+1]+, calc. 438.

Accurately prepare a mixture of 300 ml of methanol and methanesulfonic acid (V methanol / methanesulfonic acid = 4:1),It is pumped into the third reaction unit of the microreactor at a flow rate of 3.5 ml/min, and mixed with the reaction liquid flowing out from the second reaction unit.The residence time of the reaction in this step is 19 seconds, and the reaction temperature controlled by the reaction unit is 5 ° C. After the reaction liquid flows out from the third reaction unit,At the same time, the prepared mixture of boron trifluoride diethyl ether and triethylsilane was pumped into the fourth reaction unit at a flow rate of 3.5 ml/min.The residence time of the reaction unit is 15 seconds, the temperature of the fourth reaction unit is controlled to be 5 ° C, and the liquid discharged from the fourth reaction unit is continuously collected 100 ml.Finally, it was added to 200 ml of n-heptane, stirred and crystallized, and kept at 0 ° C for 1 hour, and filtered to obtain a crude product of dapagliflozin. Take a small amount of dapagliflozin for liquid chromatography analysis.The conversion ratio of the raw material A was 99.9%, and the total yield was 87.6%.

References

【1】US2011/237789,2011,A1

【2】WO2013/152476,2013,A1

【3】CN109400561,2019,A

Related articles And Qustion

See also

Lastest Price from Dapagliflozin manufacturers

US $0.00/Kg/Bag2025-04-21

- CAS:

- 461432-26-8

- Min. Order:

- 100g

- Purity:

- 99%min

- Supply Ability:

- 20kg

US $0.00-0.00/kg2025-04-21

- CAS:

- 461432-26-8

- Min. Order:

- 1kg

- Purity:

- 0.99

- Supply Ability:

- 800kg