Product no. chemwill-3GPSE-91573

highly quality and immedaite delivery

3-Glycidoxypropyltrimethoxysilane Manufacturer High quality Best price In stock factory CAS 2530-83-8

γ-glycidoxypropyltrimethoxysilane CAS 2530-83-8

Silane coupler KH-560 CAS 2530-83-8

Glymo CAS 2530-83-8

Glycidyl 3-(trimethoxysilyl)propyl ether CAS 2530-83-8

Name 3-Glycidoxypropyltrimethoxysilane

Synonyms [3-(2,3-Epoxypropoxy)propyl]trimethoxysilane; Glycidyl 3-(trimethoxysilyl)propyl ether; Glymo 3-Glycidoxypropyltrimethoxysilane; γ-glycidoxypropyltrimethoxysilane; 3-Glycidoxypropyltrimethoxy silane; γ-(2,3-epoxypropoxy)propytrimethosysilane; 3-Glycidyloxypropyltrimethoxysilane; 2,3-Epoxypropoxy propyltrimethoxysilicane; (3-Glycidyloxypropyl)-trimethoxysilane; (3-Glycidoxypropyl)trimethoxysilane; 3-(2,3-Epoxypropoxy)-propyltrimethoxysilane

3-Glycidoxypropyltrimethoxysilane Chemical Properties

Melting point -50°C

Boiling point 120 °C2 mm Hg(lit.)

density 1.070 g/mL at 20 °C

refractive index n20/D 1.429(lit.)

Fp >230 °F

storage temp. 2-8°C

form Liquid

color Clear

Specific Gravity 1.07

Water Solubility Miscible with alcohols, ketones and aliphatic or aromatic hydrocarbons. Immiscible with water.

Sensitive Moisture Sensitive

BRN 4308125

InChIKey BPSIOYPQMFLKFR-UHFFFAOYSA-N

CAS DataBase Reference 2530-83-8(CAS DataBase Reference)

NIST Chemistry Reference 3-Glycidoxypropyltrimethoxysilane(2530-83-8)

EPA Substance Registry System Silane, trimethoxy[3-(oxiranylmethoxy) propyl]-(2530-83-8)

Safety Information

Hazard Codes Xn,Xi

Risk Statements 36/38-21-52-41

Safety Statements 28A-26-36/37/39-24/25

WGK Germany 2

RTECS VV4025000

F 10-21

TSCA Yes

PackingGroup III

HS Code 29310095

MSDS Information

Appearance & Physical State Colorless transparent liquid

Density 1.07

Boiling Point 120ºC (2 mmHg)

Melting Point -50ºC

Flash Point 122ºC

Refractive Index 1.428-1.43

Stability Stable under normal temperatures and pressures.

Storage Condition 2-8ºC

Vapor Pressure 0.00213mmHg at 25°C

Safety Info

RTECS VV4025000

Safety Statements S26-S28

HS Code 29310095

Applications:

3-Glycidoxypropyltrimethoxysilane may improve dry and wet strength in cured composites reinforced with glass fiber rovings

Enhance wet electrical properties of epoxy-based encapsulate and packaging materials.

Eliminate the need for a separate primer in polysulfide and urethane sealants.

Improve adhesion in waterborne acrylic sealants and in urethane and epoxy coatings.

Application

It is mainly used in unsaturated polyester composites to improve the mechanical properties, electrical properties and light transmission properties of the composites, especially to improve their performance in wet environment.

In wire and cable industry, when used to treat EPDM system stuffed by pottery clay and crosslinked by peroxide, it can improve consumption factor and specific inductance captance.

Used for its copolymerization with monomers like vinyl acetate and acrylic acid or methacrylic, to form the polymers widely used in coatings, adhesives and sealants, providing excellent adhesion and durability.

Chemical Properties Colorless transparent liquid

Uses Pre-treatment of carbon steel with 3-(Glycidoxypropyl)trimet?hoxysilane enhances the dry and wet adhesion while reducing the cathotic disbondment rate of an epoxy coating

3-Glycidoxypropyltrimethoxysilane Preparation Products And Raw materials

Raw materials Methanol-->Silicon

3-Glycidoxypropyltrimethoxysilane Usage And Synthesis

Silane Coupling Agents KH-560 KH-560 is the first widely used coupling agent and has been used for 40 years. One end of its structure with reactive groups such as amino and vinyl, can react with epoxy, phenolic, polyester and other synthetic resin molecules. The other end is alkoxy (such as methoxy, ethoxy etc.) or chlorine atoms which is connected with silicon. These groups can be transformed into silanol in the hydrolysis in water solution or damp air. And the formed silanol is able to react with surface hydroxyl of glass, minerals and inorganic filler. Therefore, silane coupling agent is commonly used in silicate-filled epoxy, phenolic, polyester resin and other systems. In addition, it can also be used for FRP production, in order to improve its mechanical strength and resistance to wet environment. The organic groups of the silane coupling agent are selective about the reaction of the synthetic resin. Generally, these organic groups lack sufficient reactivity with synthetic resins such as polyethylene, polypropylene and polystyrene, and thus the coupling effect for them is poor. In recent years, new varieties of silane coupling agents with better coupling for polyolefins have been developed, but are limited in cost and other properties and are not yet widely used.

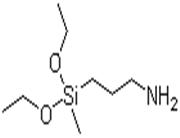

Silane coupling agent is also known as silane treatment agent. Its general formula is Y (CH2) nSiX3. Wherein n is an integer of 0 to 3; X is a hydrolyzable group such as chlorine, methoxy, ethoxy and acetoxy; Y is an organic functional group such as a vinyl, an amino, an epoxy group, a methacryloyloxy group and sulfydryl.

China

China