| Description |

Poly(methyl methacrylate), also called PMMA, is a commonly used low cost thermoplastic polymer with boundless applications to everyday life. PMMA is the most commercially important acrylic polymer and is sold under several trade names including Plexiglas® and Acrylite®. High transparency makes PMMA an ideal replacement for glass where impact or weight is a serious concern. PMMA is compatible with human tissue making it an important material for transplants and prosthetics, especially in the field of ophthalmology because of its transparency and bio-compatibility, PMMA is important in optometry for replacing the intraocular lens of cataract patient. PMMA is used as bone cement in orthopedic surgery. The modulus of elasticity is similar to natural bone giving it a more natural feeling for the patient than metallic alternatives.

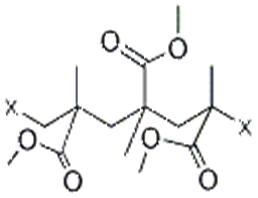

PMMA is formed through block, emulsion or suspension polymerization of methacrylic acid. PMMA was thought to be an atactic polymer through the first half of the 20th century. This means that the substituents of the molecular chain alternate randomly along the chain, which is illustrated in Figure 1A below. Since the development of modern equipment and techniques, it has been determined that the molecular chains are mostly syndiotactic (Figure 1B), meaning the molecular chain’s substituents alternate uniformly. Final processing of PMMA is accomplished through injection molding or extrusion at melt temperatures ranging from 200-230 ºC.

|

| Uses |

Poly(methyl methacrylate) is a hard, stable, non-yellowing polymer used in coating and in molded clear plastic objects, Pigment-wetting binder for coatings. Some examples of these applications are headlights and taillights on passenger automobiles, illuminated signs and street lamp housings. The polymer has also been used widely in aircraft windows as a glass replacement since WWII because of its low density and superior toughness. It is still used as a glass substitute on a wide range of sub-sonic aircraft today and has expanded to other weight sensitive applications such as race cars, motorcycles and off-road vehicles.

- It has a high degree of sheen on the surface and rigidity. PMMA is easy to shape, strong and offers limitless opportunities for colouring. PMMA is UV stable and has very good weather resistance, making it suitable for outdoor use. The electrical properties are also good. The material is not affected by alkaline solutions, diluted acids or oils, but is attacked by strong acids, acetone and alcohols. It is in the form of sheets used in shatter resistant panels for building windows, skylights, bullet proof security barriers, bathtubs, LCD screens, furniture and many other applications. It is used as the matrix in laser dye-doped organic solid-state gain media for tunable solid state dye lasers.

- PMMA has relatively low heat resistance and should be used in situations where the temperature does not exceed 55 °C. It is possible to make PMMA more impact-resistant, but this is at the expense of its good optical properties. In the field of lighting, PMMA is normally used for shades and cover plates, as well as for outdoor signs, windows, contact lenses, etc. Poly(methyl methacrylate) is used in the lenses of exterior lights of automobile and automotive components such as badges, steering wheel, tachometer covers, warning triangles and fascia panels.

- PMMA is brittle, and where microscopic notches are present it can easily break. Just like PC, it is also sensitive to being under tension, which can lead to cracks forming over time.

- Further, it is used as a shield to stop beta radiation emitted from radioisotopes, as dosimeter devices during the gamma irradiation process and as a dispersant for ceramic powders to stabilize colloidal suspensions.

|

| PMMA Microspheres |

PMMA Microspheres are spherical polymer beads that are a transparent thermoplastic synthesized from methyl methacrylate polymer. It are known for high impact and heat resistance, and good tensile and flexural strength. These strong yet lightweight polymer microspheres are often used as spacers, fillers, and reference particles for a variety of specialty applications in life sciences, medical technology, MEMS, optics and development of high performance composites.

Uncoated PMMA Microspheres

Uncoated poly(methyl methacrylate) or PMMA microspheres and spheres are often used in a wide variety of applications including porous ceramics, self assembled microfluidic devices, biomedical research and life sciences.

Silver-Coated PMMA Microspheres

Silver-coated poly(methyl methacrylate) microspheres, also known as PMMA or acrylic microspheres, are often used to create a soft slightly deformable conductive polymer spacer material. |

China

China