How to properly handle and store ethyl bromoacetate

Background

Ethyl bromoacetate, also known as ethyl bromoacetate, is an organic compound with the molecular formula BrCH2COOCH2CH3. It is a colorless or yellow liquid, its vapor is poisonous. Tears are very strong. It is insoluble in water, can be gradually decomposed by water, and is miscible with ethanol, ether and benzene [1] . Used to make military poison gas. It is strongly irritating to human eyes, skin, mucous membranes and respiratory tract.

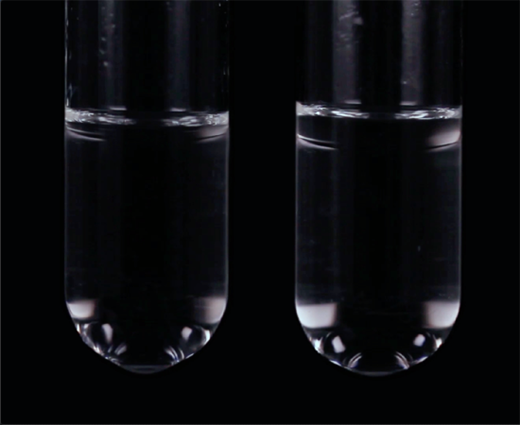

Picture 1 The physical map of ethyl dibromoacetate

A brief history of research

In 1891, Bernhardi first discovered synthesis, and its derivatives are used for therapeutic purposes and can be prepared in industrial experiments. As war ammunition, it was first used by France in fortress warfare, and was prepared before the war. In October 1914, the French used it as a gas grenade, planned for the fortress battle. On January 7, 1915, it was actually used in the forest of Argonnen on the western front of France. [2]

Preparation

First, bromine is reacted with acetic acid and acetic anhydride in pyridine to prepare bromoacetic acid, and then bromoacetic acid is reacted with ethanol in the presence of sulfuric acid to generate ethyl bromoacetate. It is generally prepared in two steps. ①Preparation of bromoacetic acid: Add 3L of glacial acetic acid and 100mL of acetic anhydride to the flask, then add 15g of red phosphorus or 70g of phosphorus tribromide, heat to 100°C with stirring, and slowly drop 300mL (900g, 5.6mol) from the separatory funnel. ) bromine, the reaction has an induction process, do not add too fast to avoid sudden reaction. After the reaction starts (with HBr released), keep it between 90 and 100 ° C, and then slowly drop 2.0 L of bromine (2.3 L in total, 41 mol), and continue to stir and heat after the addition, so that the brown-red liquid turns orange-red, Since then, there have been very few releases. Recover unreacted acetic acid until the distillation temperature reaches 140°C, and about 1 L is recovered for the next synthesis. ②Esterification: Pour the above crude bromoacetic acid into another 10L flask, add 5L industrial ethanol and 200mL sulfuric acid, reflux for 12h on a boiling water bath, wash with saturated brine three times after recovering ethanol, dry with anhydrous sodium sulfate and fractionate , Collect 154~158℃ fractions, get 2.4~2.6kg.

In a reaction flask equipped with a water separator, add 220 g (1.58 mol) of bromoacetic acid, 155 mL of absolute ethanol (2.66 mol), 240 mL of toluene and 1 mL of concentrated sulfuric acid, and then add zeolite. Heat to reflux, water, toluene, and ethanol are separated into layers in a water separator, toluene is returned to the reaction flask, the lower layer is separated, and about 75 mL is collected. Then 20 mL of ethanol was added, and the reflux reaction was continued for 0.5 h. Evaporate as much ethanol and toluene as possible. The reaction mass was poured into water, and the layers were allowed to stand. The aqueous layer was separated, washed with 5% sodium bicarbonate and water in turn, dried over anhydrous sodium sulfate, fractionated, and the fractions at 164-168°C were collected to obtain 205 g of ethyl bromoacetate with a yield of 78%. NOTE: Ethyl bromoacetate has a strong tear-inducing effect, and the entire operation should be performed in a fume hood.

Emergency release treatment

Quickly evacuate personnel from the leaked contaminated area to a safe area, isolate them, and strictly restrict access. Cut off the source of ignition. It is recommended that emergency personnel wear self-contained positive pressure breathing apparatus and protective clothing. Do not come into direct contact with spillage. Cut off sources of leaks as much as possible. Prevent flow into restricted spaces such as sewers and flood drains. Small spills: Absorb or absorb with sand or other non-combustible materials. It can also be treated with alkaline substances. Large spills: Construct dikes or dig pits for containment. Cover with foam to reduce vapor hazards. Transfer it to a tanker or a special collector with a pump, and recycle it or transport it to a waste disposal site for disposal.

Handling storage

Operation precautions: closed operation, provide sufficient local exhaust. The operation is as mechanized and automated as possible. Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear self-priming filter respirators (full face masks), one-piece adhesive tape respirators, and rubber oil-resistant gloves. Keep away from fire and heat sources, and smoking is strictly prohibited in the workplace. Use explosion-proof ventilation systems and equipment. Prevent vapors from leaking into the workplace air. Avoid contact with oxidizing agents, reducing agents, acids and alkalis. When handling, it should be lightly loaded and unloaded to prevent damage to packaging and containers. Equipped with the corresponding variety and quantity of fire fighting equipment and leakage emergency treatment equipment. Empty containers may be harmful residues.

Storage precautions

Store in a cool and ventilated warehouse, away from fire and heat sources, the temperature of the warehouse should not exceed 30 °C, prevent direct sunlight, keep the container sealed, and store it separately from oxidants. equipment and tools. When filling, pay attention to the flow rate (not more than 3m/s) and have a grounding device to prevent static accumulation, and lightly unload during handling to prevent damage to the packaging container.

Reference

1 Neng Ting. Dictionary of Organic Synthesis. Beijing: Beijing Institute of Technology Press, 1992.01:354

2 Fu Zhifeng, Liu Haitao, Shi Yan, Jiao Shuke. Synthesis of ABA-type block copolymers using ethyl α,α-dibromoacetate as a bifunctional initiator. "Journal of Chemistry of Higher Education Institutions", 2000

See also

Lastest Price from Ethyl bromoacetate manufacturers

US $0.00-0.00/KG2025-04-21

- CAS:

- 105-36-2

- Min. Order:

- 1KG

- Purity:

- 99%

- Supply Ability:

- 1000 MT

US $0.00/kg2025-03-07

- CAS:

- 105-36-2

- Min. Order:

- 1kg

- Purity:

- 0.99

- Supply Ability:

- 20tons