Benzyltriethylammonium chlorideuses

General description

Triethylbenzylammonium chloride, English name Benzyltriethyl-ammonium chloride, TEBA for short, molecular formula C13H22ClN, relative molecular weight 228.78, white crystal or powder, easy to absorb moisture, melting point 185 ℃, soluble in water, ethanol, methanol, Isopropanol, DMF, acetone and dichloromethane are insoluble in organic solvents such as ether and benzene. TEBA is a benzyl quaternary ammonium salt cationic surfactant. It is a widely used phase transfer catalyst and has a wide range of applications in scientific research and production.[1]

Figure 1 the molecular formula of Benzyltriethylammonium chloride

Application and pharmacokinetics

1.As a cationic surfactant, it is mainly used as a disinfectant, hydrophobic agent, corrosion inhibitor and deemulsifier. As a phase transfer catalyst, it is widely used in organic synthesis and polymer polymerization. It is used in pesticides, perfumes, photographic materials and It has applications in medicine and other fields. In organic synthesis, it can be used for C-alkylation, O-alkylation, N-alkylation, S-alkylation and other alkylation reactions, -CN and -F nucleophilic substitution reaction, carbene reaction, oxidation reaction, reduction reaction, Darzen condensation, Wittig-Hormar synthesis and other reactions have outstanding catalytic effects and are highly favored by chemists.[2]

2.Taking potassium erucate/trihydroxyethylbenzylammonium chloride worm-like micelles as the research object, the mixture of styrene and twin-tail substituted acrylamide was solubilized into the worm-like micelles and polymerized. The apparent viscosity of a series of worm-like micelles is measured by the viscosity method, with the purpose of obtaining worm-like micelles with high apparent viscosity and good temperature resistance, which are better used in fracturing fluids, tertiary oil recovery and other fields.[3]

Synthesis

The synthesis is often produced by the atmospheric pressure method, and there is no special requirement for the equipment.During the reaction, the product is a solid, which will affect the full reaction of the raw materials, so consider adding a solvent.

1.Wu Mingshu et al. [1] used DMF as a solvent and ethyl acetate as a catalyst to synthesize TEBA. The process conditions are: 10 mL of benzyl chloride, 12.64 mL of triethylamine, 6.66 mL of DMF, 2 mL of ethyl acetate, the reaction temperature is about 104°C, the reaction time is 1 h, and benzene is used as the precipitant.The reaction time is short and the reaction yield is improved.

2. Weng Yuankai et al. [2] used absolute ethanol as a solvent and used gas chromatography to track the changes in the concentration of benzyl chloride over time to synthesize TEBA.The process conditions are: benzyl chloride 6.38 g (0.05 mol), triethylamine 5.08 g (0.05 mol), anhydrous ethanol 37.2 mL, reaction time 3.5 h, and the reaction solution is placed Overnight, the yield was 79%.

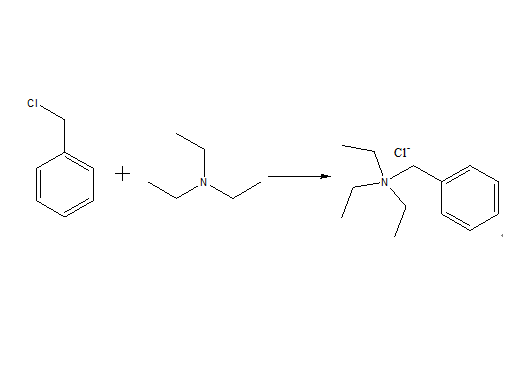

Benzyltriethylammonium chlorideuses as the main raw materials to undergo a quaternary amination addition reaction. The reaction equation is as follows:[4]

Figure 2 The synthesis route of Benzyltriethylammonium chlorideuses

In order to increase the product yield, a method of making an excess of a raw material is usually adopted. Experiments show that the excessive amount of benzyl chloride as the raw material is more beneficial to increase the yield than the excessive amount of triethylamine as the raw material.Moreover, industrial benzyl chloride is about 7000 yuan/ton, which is much cheaper than industrial triethylamine, which is about 2000 yuan/ton. In terms of reducing production costs, excessive benzyl chloride is more economical and practical. The solvent has high polarity and low solubility to the product.

Toxicity and storage

Toxicity classification: acute toxicity intravenous - mouse LD50: 18 mg / kg flammability hazard characteristics; Toxic nitrogen oxide and chloride smoke generated by combustion, storage and transportation characteristics, low temperature ventilation and drying; Store food raw materials separately from the warehouse. Fire extinguishing agent dry powder, foam, sand, carbon dioxide, fog water Fire extinguishing agent dry powder, foam, sand, carbon dioxide, fog water.

References

1.Optimization of synthesis process of benzyltriethylammonium chloride with high yield

2. "K. C. BAYAN and H. K. DAS,".

3.Li Ni, Zhang Rui: "Viscosity Behavior of Worm-like Micelles of Potassium Erucate/Trihydroxyethylbenzylammonium Chloride", Progress in Chemical Industry, Issue 11, 2015, pp. 3995-4000.

4.Li Gan, Xu Huibin: "Research Progress in the Synthesis of Triethylbenzylammonium Chloride", "Yunnan Chemical Industry" 2014, Issue 3, pages 29-35.

5.Wu Mingshu, Peng Cunyao. Synthesis of triethylbenzylammonium chloride[J]. Hebei Chemical Industry, 1992(12): 6-7.

6.Weng Yuankai, Huangshan, Cao Liangfeng. Synthesis reaction kinetics of triethylbenzylammonium chloride[J]. Jiangsu Chemical Industry, 1993, 21(2): 17-18, 36, 56

You may like

Related articles And Qustion

Lastest Price from Benzyltriethylammonium chloride manufacturers

US $0.00/KG2025-05-08

- CAS:

- 56-37-1

- Min. Order:

- 1KG

- Purity:

- 98%min

- Supply Ability:

- 30tons/month

US $0.00/KG2025-04-21

- CAS:

- 56-37-1

- Min. Order:

- 1KG

- Purity:

- 99%

- Supply Ability:

- 1000 MT