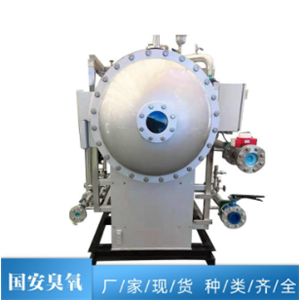

Product name:Mud Cleaner

Item:HQJ250-100

Details:

HQJ series drilling fluid desanding and desilting integrated mud cleaner, or integrated cleaner for short, is used for separating the solid-phase granules in the drilling fluid after treated by the shale shaker.

The integrated cleaner can integrate a group of desander and desilter on one shale shaker, The drilling fluid firstly pass the desander or desilter for separation, with overflow returning to the circulatory system and the bottom flow screened and treated by the shale shaker, If necessary, the shale shaker of the integrated cleaner could be used as the forestage shale shaker.

The cyclone mixer is made of wearing-resistant special polyurethane material, which has good performance in fluid erosion resistance. The feeding port if designed to have a tangent feed and smooth transition, beneficial for improved separation efficiency. It is smooth in structure and ration flow channel.

The desilter is distributed in a round pattern, making the cyclone mixers bear uniformed pressure and flow.

Technical Parameter table

Power of motor of shaker: 2-1.865 kW

Vibration amplitude of shaker: ≥5 mm

Screen stencil of shaker: 3-1053×697 crochet screen stencil

Diameter of desanding cyclones: 250 or 300mm

Number of desanding cyclones: 2 or 3

Handling capacity of desander: 250 type: 70-80 m3/h for each one;

300 type: 90-100 m3/h for each one.

Particle diameter of desander: 250 type: 40~100μm; 300 type: 50~150μm.

Diameter of desilting cyclones: 100 or 125mm

Number of desilting cyclones: 12, 16 or 20

Handling capacity of desilter: 100 type: 13-15 m3/h for each one;

125 type: 17-19 m3/h for each one.

Particle diameter of desilter: 100 type: 20~40μm; 125 type: 25~50μm.

Power of feed pump: 55~75kW

Working pressure: 0.2~0.4 MPa

Weight: 3000~3100 kg

Linear Shale Shaker,Mud Shale Shker