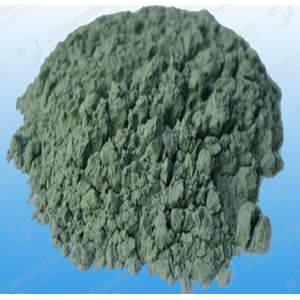

光学晶体抛光粉/研磨抛光级黑色碳化硅F500#水洗微粉

Black silicon carbide

¥18

25公斤

起订

¥17

1000公斤

起订

河南 更新日期:2026-01-05

产品详情:

- 中文名称:

- 黑色碳化硅F500#

- 英文名称:

- Black silicon carbide

- CAS号:

- 12070-04-1

- 品牌:

- 海旭磨料

- 产地:

- 河南

- 保存条件:

- 干燥通风

- 纯度规格:

- 98%

- 产品类别:

- 金刚砂

- 颜色/外观:

- 灰黑色粉末

- 别名:

- 黑色碳化矽

- 分子式:

- SiC

- 执行质量标准:

- GB/T 2480-2022

- 型号:

- F500

- 货号:

- C F500

- 比重:

- 3.2g/cm3

- 硬度:

- 莫氏9.2

- 堆积密度:

- 1.2-1.6g/cm3

- 耐火温度:

- 1850度

公司简介

郑州市海旭磨料有限公司成立于1999年7月,主要从事各种磨料的研发,生产,销售等相关业务。主打白刚玉,棕刚玉,碳化硅,铬钢玉,玻璃珠,石榴石,板状刚玉等。我们从事磨料磨具生产和贸易几十年来,秉承质量第一,信誉至上的原则,不断开拓进取,为国内外合作伙伴提供优质产品和高效服务。

2002年我公司被郑州市技术监督局授予“产品质量信得过,售后服务信誉好”的双信单位。并于2004年通过ISO9001:2000质量管理体系认证。

目前,公司产品已远销东南亚,非洲,欧洲等90多个国家和地区,赢得了众多客户一致好评。

| 成立日期 | (27年) |

| 注册资本 | 100万人民币 |

| 员工人数 | 1-10人 |

| 年营业额 | ¥ 100万以内 |

| 经营模式 | 工厂 |

| 主营行业 | 非金属矿,其他仪器耗材 |

黑色碳化硅F500#相关厂家报价 更多

-

- 绿碳化硅

- 淄博淄川道新磨料磨具公司

- 2026-02-15

- 询价

-

- 绿碳化硅

- 辽阳宏图碳化物有限公司

- 2026-02-15

- 询价

-

- 纳米碳化硅、微米碳化硅、超细碳化硅 贝塔碳化硅 阿尔法碳化硅SiC

- 上海杳田新材料科技有限公司 VIP

- 2025-11-22

- 询价

-

- 纳米碳化硅

- 上海超威纳米科技有限公司

- 2025-08-19

- 询价

-

- Green silicon carbide

- -

- 2013-04-23

- 询价