Product Name: Polydextrose

Synonyms: Unii-vh2xou12ie;Polydextrose (200 mg);Polydextrose type 2;Water-soluble dietary fiber;POLYDEXTROSE;Poly-D-glucose;POLYDEXTROSE,UNTREATED,FCC;dextrose/ sorbitol condensation polymer

CAS: 68424-04-4

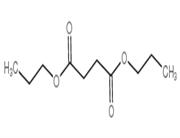

MF: C12H22O11

MW: 342.29648

EINECS: 614-467-9

Product Categories: Food additive and sweetener

Mol File: 68424-04-4.mol

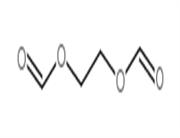

Polydextrose Structure

Polydextrose Chemical Properties

Melting point >130°

solubility Completely miscible in water. Sparingly soluble to insoluble in most organic solvents. Polydextrose has a higher water solubility than most carbohydrates and polyols, allowing the preparation of 80% w/w solutions at 20°C. Polydextrose is soluble in ethanol and only partially soluble in glycerin and propylene glycol.

Safety Information

HS Code 3913901000

MSDS Information

Polydextrose Usage And Synthesis

Chemical Properties Polydextrose occurs as an odorless, off-white to light tan powder with a bland, slightly sweet to slightly tart taste, dependent upon grade. Polydextrose is also available as a clear, light yellow to colorless liquid (70% dry substance), which is odorless with a slightly sweet taste.

Uses Bulking agent for reduced calorie foods.

Uses Polydextrose is a bulking agent that is a randomly bonded conden- sation polymer of dextrose containing small amounts of bound sor- bitol and citric acid. it is a water-soluble powder providing a ph range of 2.5–3.5. it is partially metabolized which results in a caloric value of 1 cal/g. as a reduced-calorie bulking agent, it can partially replace sugars and in some cases fats in reduced-calorie foods. it also functions as a bodying agent and humectant. applications include desserts, specific baked goods, frozen dairy desserts, chewing gum, and candy. usage levels vary according to application, but examples are frozen dessert, 13–14%; puddings, 8–9%; and cake, 15–16%.

Production Methods Polydextrose is prepared by the bulk melt polycondensation of glucose and sorbitol in conjunction with small amounts of foodgrade acid in vacuo. Further purification steps are then involved to generate a range of products with improved organoleptic properties by the removal of acidity and flavor notes generated during the condensation reaction. A partially hydrogenated version of polydextrose, which is suited for high inclusion rates, for sugar-free applications, and where Maillard reactions are not required, is also available.

China

China