1/2

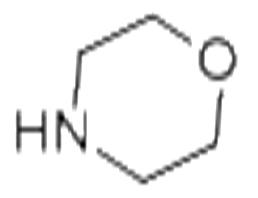

Morpholine

$ 1.00

/1KG

- Min. Order1G

- Purity98%

- Cas No110-91-8

- Supply Ability100KG

- Update time2019-07-06

career henan chemical co

VIP8Y

China

China

Since:2014-12-17

Address:Zhengzhou High tech Zone, Henan Province, China

Enterprise Verified

Business Bank account

Basic Contact Infomation

Business Address

Trade Company

Chemical Properties

| Product Name | Morpholine |

| CAS No | 110-91-8 |

| EC-No | |

| Min. Order | 1G |

| Purity | 98% |

| Supply Ability | 100KG |

| Release date | 2019/07/06 |

AD68

| Morpholine Basic information |

| Product Features Chemical properties Uses metal corrosion inhibitors rubber vulcanization acceleratorquantitative analysis Production method Hazards & Safety Information |

| Product Name: | Morpholine |

| Synonyms: | 1,4-Oxazinan;1,4-oxazine,tetrahydro-;2H-1,4-Oxazine, tetrahydro-;4H-1,4-Oxazine, tetrahydro-;BASF 238;basf238;Diethylenimide oxide;diethylenimideoxide |

| CAS: | 110-91-8 |

| MF: | C4H9NO |

| MW: | 87.12 |

| EINECS: | 203-815-1 |

| Product Categories: | Organic Chemicals;BasesChemical Synthesis;Organic Bases;Supported Reagents;Supported Synthesis;Synthetic Reagents;ACS Grade;Building Blocks;C4 to C10;Chemical Synthesis;Essential Chemicals;Heterocyclic Building Blocks;Inorganic Salts;Morpholines/Thiomorpholines;Research Essentials;Solutions and Reagents;Organic solvents;Thiophenes |

| Mol File: | 110-91-8.mol |

|

|

| Morpholine Chemical Properties |

| Melting point | -5 °C |

| Boiling point | 129 °C(lit.) |

| density | 1.000 g/mL at 20 °C |

| vapor density | 3 (vs air) |

| vapor pressure | 31 mm Hg ( 38 °C) |

| refractive index | n |

| Fp | 96 °F |

| storage temp. | Store at R.T. |

| solubility | water: miscible |

| form | Liquid |

| pka | 8.33(at 25℃) |

| color | APHA: ≤15 |

| PH | 11.2 (H2O)(undiluted) |

| explosive limit | 1.4-15.2%(V) |

| Water Solubility | MISCIBLE |

| FreezingPoint | -4.9℃ |

| Sensitive | Hygroscopic |

| Merck | 14,6277 |

| BRN | 102549 |

| Stability: | Stable. Flammable. Incompatible with strong oxidizing agents, strong acids, acid chlorides, acid anhydrides. Hygroscopic. |

| InChIKey | YNAVUWVOSKDBBP-UHFFFAOYSA-N |

| CAS DataBase Reference | 110-91-8(CAS DataBase Reference) |

| NIST Chemistry Reference | Morpholine(110-91-8) |

| EPA Substance Registry System | Morpholine(110-91-8) |

| Safety Information |

| Hazard Codes | C |

| Risk Statements | 10-20/21/22-34 |

| Safety Statements | 23-36-45 |

| RIDADR | UN 2054 8/PG 1 |

| WGK Germany | 3 |

| RTECS | QD6475000 |

| TSCA | Yes |

| HazardClass | 8 |

| PackingGroup | I |

| Hazardous Substances Data | 110-91-8(Hazardous Substances Data) |

| Toxicity | LD50 orally in female rats: 1.05 g/kg (Smyth) |

| Morpholine Usage And Synthesis |

| Product Features | Morpholine, also known as 1, 4-oxazepine and diethylenimine oxide, is a kind of colorless alkaline oily liquid. It smells of ammonia and has hygroscopicity. Morpholine could evaporate with water vapor and miscible with water. It is Soluble in acetone, benzene, ether, pentane, methanol, ethanol, carbon tetrachloride, propylene glycol and other organic solvents. Morpholine Vapor could form an explosive mixture with air and the explosion limit is 1.8% to 15.2% (volume fraction). Morpholine is a secondary amine, and at the same time it has the property of inorganic acid and organic acid, so that it can generate salt and amide. Morpholine contains secondary amine groups and it has all the typical reaction characteristics of the secondary amine groups. It can react with inorganic acid to form a salt, and also can react with organic acid to form salt or amide. Morpholine can carry out alkylation reactions and it also carry out ketone reaction or Willgerodt reaction with ethylene oxide. Because of the unique chemical properties of morpholine, it has become one of the important petrochemical products with important commercial application. It can be applied to produce rubber vulcanization accelerators such as NOBS, DTOS and MDS. And it is also applied to produce anti-corrosives, anti-corrosion agents, detergents, detergents, analgesics, local anesthetics, sedatives, respiratory and vascular stimulants, surfactants, optical bleach, fruit preservatives, and textile dyeing auxiliaries. Morpholine also has a wide range of applications in the field of rubber, pharmaceuticals, pesticides, dyes, coatings and other industries. In medication it could be applied in the production of morpholine guanidine, virus Ling, ibuprofen, cough must, naproxen, dichloroaniline, sodium phenylacetate and other important drugs. The two main production method of morpholine are DEA method (diethanolamine method) and DEA method (diethylene glycol method) It is noteworthy that new polymer monomer acrylic morpholine has obtained a rapid development in recent years. Acrylic acid morpholine could be produced from the reaction between acrylic acid and morpholine. And acrylic acid morpholine is a kind of water-soluble monomer, and it is still water-soluble after the polymerization. So it could be applied for the modification of aqueous polymers. Besides, acrylic morpholine is widely used as a reactive diluent for UV curable resins. With the deepening of applied research, many new specific uses have been developed and it becomes polymer monomer with rapid development.  Figure 1 for the morpholine structure |

| Chemical properties | It is colorless water-absorbing oily liquid and it smells ammonia. It is soluble in water and methanol, ethanol, benzene, acetone, ether, ethylene glycol and other commonly used solvents. |

| Uses | (1) For medicine, it used as the raw materials for rubber accelerator and fluorescent whitening agent. (2) Morpholine is the intermediates of fungicide dimethomorph and flumorpholine and organophosphate insecticide phosalphos. (3) Morpholine is Mainly used for the production of rubber vulcanization accelerator, but also for surfactant, textile auxiliaries, pharmaceuticals, pesticide synthesis. (4) Morpholine also used as a catalyst for polymerization of butadiene, corrosion inhibitors, optical bleach, the goods are dyes, resins, wax, early glue, casein and other solvents. At present, the total production of morpholine in the world is 3-4 million t/a. (5) Morpholine salts are also widely used. Morpholine salts like morpholine hydrochloride (10024-89-2) are the organic synthesis of intermediates. Morpholine fatty acid salt can be used as the coating agent of fruits or vegetables epidermal coating agent, and it could inhibit the base respiration and prevent the epidermis from evaporation of water and epidermal atrophy. (6) Morpholine is the main raw materials of accelerator NOBS. for analysis reagents and resins, wax, shellac and other solvents, used in the production of sodium sulfate. Water glass and ultramarine. Also used in the manufacture of glass. Paper. Detergent. Soap. Dye. Synthetic fiber. Tanning. Medicine and ceramics industries. Analysis reagents, such as nitrogen determination, dehydrating agent. (7) Morpholine is used for the analysis of reagents and resins, wax, casein, shellac and a variety of solvents solvent. (8) Morpholine could produce salt after reacting with inorganic acid, and it also could produce salt or amide after reacting with organic acid. It also can be alkylated, and it also could come up a ketone reaction or Willgerodt reaction with ethylene oxide. |

| metal corrosion inhibitors | As a kind of metal corrosion inhibitor, Morpholine is mainly applied for the anti-corrosion of iron, copper, zinc, lead and other metals. It remains at its starting stage in China, but outside the country, a considerable proportion of Morpholine are used as a kind of anti-rust agent for metal gas to prevent the metal corrosion caused by atmosphere and it has been widely used in the field of mechanical instruments, automobiles, medical equipment and others. The metal atmospheric rust inhibitor used earlier such as dicyclohexylamine nitrite and cyclohexylamine do harm to the human body and they are more environmentally toxic. Instead, morpholine as a metal gas-liquid corrosion inhibitor, it has the advantages of low toxicity, so the foreground is prosperous. |

| rubber vulcanization accelerator | Before 1990's, in Europe, the United States, Japan and other developed areas, the consumption of rubber vulcanization accelerator accounted for more than 50% of the total demand for morpholine. At present, more than 30% consumption of rubber vulcanization accelerator is used for NOBS. In recent years, the toxicity issue of the harmful nitrosamines in the accelerator which produced during rubber processing is driving more attention internationally. A number of restrictive laws and regulations are introduced all around the world. For example, in Germany as early as 1982, the law about the regulations issued nitrosamine content control was established. The United States, Japan, France, the United Kingdom actively developed new vulcanization accelerator which don’t produce nitrosamine, and they have stopped using nitrosamine which will produce vulcanization accelerator. Therefore, the consumption of morpholine in foreign countries has decreased with banning of the accelerator NOBS year by year. In China however, we have no corresponding regulations prohibited about banning accelerator NOBS. But China has joined the WTO, due to a large number of foreign enter and high requirement about additives localization, it requires more environmental protection in China's rubber vulcanization accelerator. Using non-toxic promoter and replacing NOBS becomes the general trend. China's demand for NOBS is significantly reduced in recent years. China will no longer use basic decomposition of nitrosamine secondary amine accelerator. As the main substitute of NOBS, NS (N-tert-butyl-2-benzothiazole sulfonamide), which does not produce nitrosamines, has a large production capacity. In 2005, the output was 14,000 tons and it is 10.1%, of the total amount. So there was good development momentum. |

| quantitative analysis | Get 4 parts of methanol solution with 0.1% of bromocresol green and 1 part of 0.1% aqueous solution with 0.1% of methyl red sodium salt. Mix them and put aside to use as a mixed indicator later. Get 50ml water in 250ml flask, add 0.4ml mixed indicator, drop 0.1moI/L hydrochloric acid, and wait for the color to turn green. Accurately weighs the sample 1.4~1.6g, add the flask and mix it. Use 0.5mol/L hydrochloric acid titration and wait for the color to turn green. Per ml, 0.5mol/L hydrochloric acid is equivalent to 43.56mg C4H9NO. |

| Production method | (1) Morpholine could be produced by diethanolamine dehydration cyclization derived from sulfuric acid. Add diethanolamine to the water reaction pot and drop sulfuric acid in the temperature of 60 ℃, then when the temperature heat at 185-195 ℃, incubate it for 30min. Cool it to under 60℃ and drop sodium hydroxide solution to pH = 11. The next steeps are cooling, filtering, filtrating distillation, collecting the following fractions below 130℃. The content of spermine is suppose to reach more than 99.5%. The method is easy to obtain raw materials, so it has become the main method of producing morpholine in the world. Morpholine also could be produced in the catalytic reaction between dioxane and ammonia gas. (2) The preparation method is that we could get Morpholine from the presence of sulfuric acid dehydration cyclization diethanolamine In the presence of sulfuric acid ; then add diethanolamine into the reaction kettle and add H2SO4 at a temperature of below 6 °C, then heat it to 185-195 °C for 30 minutes, cool to 60 °C. Drop NaOH solution to pH = 11, and the last two steeps is cooling and filtrating. Morpholine could be collected from the fraction below 130 °C. We can also get morpholine from the reaction between diethylene glycol and ammonia in the presence of catalyst and pressure. The method is easy to obtain raw materials, thus it is the main method of producing morpholine around the world. |

| Hazards & Safety Information | category: Flammable liquids toxicity grading: Poisoning acute toxicity: Oral-rat LD 50: 1050 mg/kg; oral-mouse LD 50: 525 mg/kg Stimulating data: Skin-rabbit 995 mg/24 h severe; eye –rabbit 2 mg severe. hazardous characteristic of explosive: Will cause explosion when it mixes with steam and air hazardous characteristic of flammability: Flammable; combustion produces toxic chloride gas transportation and storing properties: Store it in low temperature, dry and ventilated environment. Prevent from fire, friction,spark and Separated from oxidant extinguishant: Water spray, dry chemical powder, foam or carbon dioxide occupational standards: TLV-TWA 70 mg/m3 STEL 105 mg/m3 |

| Chemical Properties | Yellow liquid |

| General Description | An aqueous solution with a fishlike odor. Corrosive to tissue and moderately toxic by ingestion and inhalation. |

| Air & Water Reactions | Highly flammable. Water soluble. |

| Reactivity Profile | MORPHOLINE dissolved in water neutralizes acids in exothermic reactions to form salts plus water. May be incompatible with isocyanates, halogenated organics, peroxides, phenols (acidic), epoxides, anhydrides, and acid halides. Flammable gaseous hydrogen may be generated in combination with strong reducing agents, such as hydrides. |

| Health Hazard | May cause toxic effects if inhaled or ingested/swallowed. Contact with substance may cause severe burns to skin and eyes. Fire will produce irritating, corrosive and/or toxic gases. Vapors may cause dizziness or suffocation. Runoff from fire control or dilution water may cause pollution. |

| Fire Hazard | Flammable/combustible material. May be ignited by heat, sparks or flames. Vapors may form explosive mixtures with air. Vapors may travel to source of ignition and flash back. Most vapors are heavier than air. They will spread along ground and collect in low or confined areas (sewers, basements, tanks). Vapor explosion hazard indoors, outdoors or in sewers. Runoff to sewer may create fire or explosion hazard. Containers may explode when heated. Many liquids are lighter than water. |

Company Profile Introduction

Established in 2014,Career Henan Chemical Co. is a manufacturerspecializing in the sale of fine chemicals. Mainly deals in the sales of: Pharmaceutical intermediates OLED intermediates: Pharmaceutical intermediates; OLED intermediates;