| Applications |

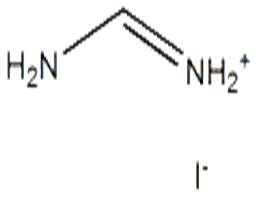

Formamidinium lead iodide shows a narrower bandgap than the commonly used methylammonium lead iodide (1.48 eV compared to ~1.57 eV), and hence lies closer to that favourable for optimum solar conversion efficiencies. Spin-coating the formamidinium iodide (FAI) plus PbI2 precursor solution in N,N-dimethylformamide (DMF) initially resulted in discontinuous perovskite films. However, by adding a small amount of hydroiodic acid (HI) to the stoichiometric FAI, extremely uniform and continuous films were formed.

Controlled humidity is another deciding factor that affects the film morphology, crystallinity, and optical and electrical properties of FAPbI3 [2]. 16.6% PCE was achieved with low relative humidity of 2%, with the device efficiency dropped to about half (8.6%) when the humidity was 40%.

Low-volatility additives such as FACl and MACl are good candidates for assisting in the crystallisation of phase pure α-FAPbI3 via the formation of intermediate mixtures, which prohibits the crystallisation of the δ-FAPbI3 phase. It also has been observed that the black perovskite-type polymorph (α-phase), which is stable at relatively high temperatures (above 160 oC), turned into the yellow FAPbI3 polymorph (δ-phase) in an ambient humid atmosphere. Results show that incorporation of MAPbBr3 into FAPbI3 stabilises the perovskite phase of FAPbI3 and improves the power conversion efficiency of the solar cell to more than 18% under a standard illumination of 100 mW/cm2.

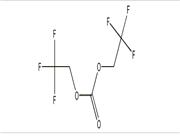

With an approach of FAPbI3 crystallisation by the direct intramolecular exchange of dimethylsulfoxide (DMSO) molecules intercalated in PbI2 with formamidinium iodide, device with performance over 20% has been fabricated. |

China

China